Elevator and Escalator

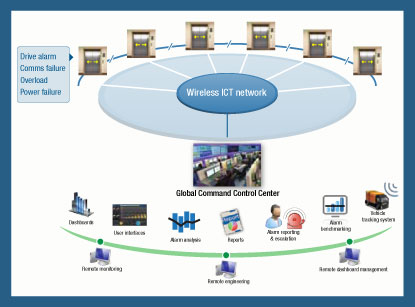

Manufacturers can offer support services, predictive maintenance and to reduce emergency call-outs, with alarms handled in the GCCC to ensure rapid response 24X7

Modern elevator management systems use IT to provide building staff with a comprehensive interface to monitor and control an array of elevator, escalator and moving-walk functions. These systems can be linked to a Pacific Controls M2M data panel in order to transfer data from proprietary systems at the site onto the IP network for transmission to the GCCC or for integration with the manufacturer’s own enterprise management software. This approach gathers real-time information to be collated on a cloud-computing platform and accessed from any location using any web enabled device. Manufacturers can use Pacific Controls Managed Services for Critical Assets Monitoring to offer support services, predictive maintenance and to reduce emergency call-outs, with alarms handled in the GCCC to ensure rapid response 24x7. The service aids elevator companies’ response to a number of key challenges:

- Continually enhancing service levels and customer satisfaction while delivering services at an optimum price point

- Avoiding revisits by service engineers undertaking routine maintenance to minimise the use of resources and the cost of service contracts

- Minimising the number of breakdowns and, when they occur, knowing which is the closest support team available to deal with the problem.

Pacific Controls M2M Elevator and Escalator Monitoring

Pacific Controls ICT Enabled Managed Services for Business Process Integration make more data available about system performance and more preventive maintenance becomes possible. Using the predictive capabilities of the Pacific Controls service means that breakdowns become extremely rare and the cost of providing support services can be substantially reduced. Modernising elevators reduces the risk of breakdowns and the frequency of maintenance and allows IT management systems to be added, including the M2M data gathering panels from Pacific Controls.

By installing a data gathering panel from Pacific Controls, elevator manufacturers gain access to a state-of-the art maintenance management system and also to Gbots, intelligent software robots that can carry out maintenance tasks remotely. This helps to address elevator suppliers’ challenges in five key areas:

- Managing alarms 24x7 so that emergency alarms are sent to service engineers immediately and less critical issues are scheduled for timely attention

- Reducing breakdowns by monitoring the elevator and identifying degrading performance so that they can be serviced before a breakdown occurs

- Minimising the number of visits by service engineers by scheduling routine maintenance based on knowledge of the use and performance of each elevator or escalator

- Providing service engineers with detailed information about any faults and problems that are developing so that they have the right tools and parts with them on the first visit

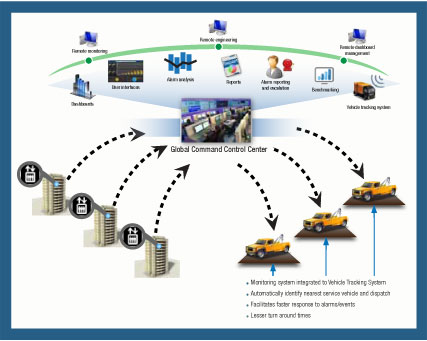

- Providing information about the exact location of the faulty system and the nearest available repair crew.

Pacific Controls’ maintenance management systems can handle alarms from elevator systems worldwide, in real time, whatever the local data format. Pacific Controls onsite data panel will integrate all IT-enabled elevator systems using whatever interface is available. Pacific Controls cutting edge fleet management system (described in section 6) can be used to optimise the schedules of service teams, reduce unnecessary journeys and fuel use, ensure that the vehicles are maintained and that the drivers’ performance is monitored.

Using Pacific Controls Managed Services for Critical Assets Monitoring allows elevator and escalator manufacturers to create a comprehensive database of information for their entire portfolio of installed equipment. The system unifies the data, making it comparable, and uses artificial intelligence, data mining techniques, trend prediction and modelling to deliver meaningful results in a range of dashboards and reports.

Pacific Controls has broken the cost barrier that now allows manufacturers to connect elevators and escalators to the M2M network and take advantage of the advances in technology that create the Internet of Things. Elevator manufactures can now collect all the possible performance data from their entire portfolio of products and have every escalator monitored and controlled from a central platform that allows them to set targets and analyse performance based on a wealth of data. This gives a complete picture of the usage and performance of their equipment, which in turn can become the basis for a long-term relationship with their customers.

Benefits for Elevator and Escalator Suppliers

Pacific Controls ICT Enabled Managed Services For Business Process Integration bring long-term benefits to elevator and escalator manufacturers as they assist in delivering higher value to the customers and in positioning the product in a premium quality market space. Having a wealth of real-time data available about the elevators and escalators and their patterns of use allows manufacturers to plan modernisation programmes for their customers and target their sales efforts at customers whose equipment is most in need of modernisation. They can benchmark performance, monitor KPIs and make staff accountable for the quality of their work. Manufacturers can provide more off-site technical support, with the aid of the detailed information collected by the M2M system and by using Pacific Controls revolutionary Gbot technology to take action remotely in the control system. They can make the maintenance and emergency services more cost effective by predicting equipment performance from trends in the data, which allows engineer visits to be scheduled in a timely manner. Real-time information about the location of vehicles and support staff allows managers to plan their calls efficiently to reduce operations cost. The managed services will contribute to meeting Corporate Social Responsibility targets. Using ICT to monitor equipment and manage maintenance programmes can lead to environmental benefits and can significantly reduce the company’s carbon footprint.

Collating the data in one system allows the company to develop troubleshooting guidelines based on the history of faults that have developed and the solutions that were found. This in turn will help to improve the quality of their elevators and escalators based on detailed performance data that provides valuable input for product R&D.

Benefits for Owners of Elevators and Escalators

Building owners avoid disruption to shoppers and travellers because of the improved reliability and increased uptime of their elevators and escalators. They gain peace of mind and reduce the cost of ownership as equipment life is extended and maintenance becomes more efficient.