Energy Management

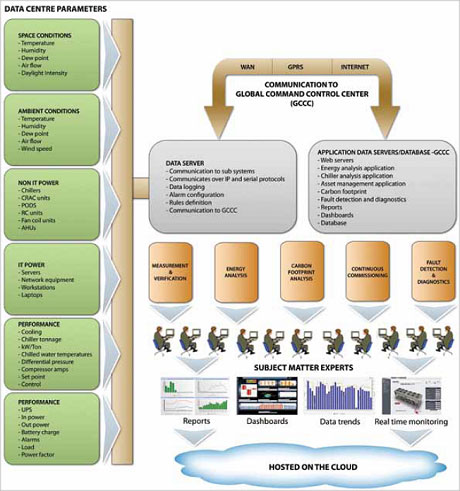

JADC uses Pacific Controls’ world-leading energy management services to ensure that the facility has the smallest possible carbon footprint. Its state-of-the-art NOC is staffed by highly qualified energy experts. Its energy monitoring and analysis tools utilise a compendium of technologies, innovative software and communication infrastructure.

Energy use and related operational data are monitored in real time, logged, archived and communicated over data networks to the NOC in the Data Center. The software at the NOC generates a wide range of reports, designed to meet the needs of the Data Center operation and management team and their customers.

JADC uses Computational Fluid Dynamics (CFD) to create a virtual model of the airflow in the facility and to find ways to maximise the cooling effect, which further drives down cooling costs. CFD provides a detailed 3-D analysis of how cold air is moving through the Data Center, identifying potential hotspots where equipment is receiving too little airflow. Thermal mapping can also locate areas that are receiving more cold air than is needed.

This state-of-the-art energy management suite has five components:

Measurement and Verification

The measurement and verification module serves as the base for the other Data Center management components. It offers real-time, verified statistics necessary for assessing the energy and power efficiency of the Data Center and its supporting infrastructure.

Energy Analysis

The energy analysis component proactively logs and archives the energy consumption of the different components at predetermined intervals. The archived information is then analysed by the software to provide the Data Center manager with an energy profile for each separate component, each aisle and the facility as a whole.

Carbon Footprint Analysis

This module tracks the total amount of CO2 released by the data centre and provides statistics on the overall carbon footprint on a periodic basis. This is used to formulate strategies for mitigating the carbon footprint of the computing infrastructure.

Continuous Commissioning

Continuous commissioning is a process of fine-tuning the operation of the HVAC equipment. Any environmental and operational problems are rectified by Gbots that intelligently and automatically, adjust control settings and actuators.

Fault Detection and Diagnosis

Fault detection and diagnosis is one of the most important tools in the Data Center management toolbox. Pacific Controls has developed an advanced fault detection system using intelligent Gbots, autonomous software robots deployed across networks that are capable of identifying even minor issues in the Data Center facility. In some cases the Gbots can rectify the problem themselves and, if not, the software generates work orders for resolving the issues detected.

The graphic referenced in figure 2 summarises the deployment of these five strategic services which are explained in detail in the following section.