- ICT - Information & Communications Technology

- Video Surveillance as a Service (VSaaS)

- Fourth Utility - ICT Design

- Controls on Cloud

- Global Command Control Center

- Software as a Service

- Managed Services

- Green Data Centers

- Global Engineering Services

- Machine to Machine (M2M)

- Airport Automation

- Hotel Automation

- Integrated Building Automation

- e-Enabled Green Homes

- Vehicle Tracking System

- Green Building Design Services

- XaaS

View e-brochure

View e-brochure

View e-brochure

View e-brochure

View e-brochure

View e-brochure

Information and Communications Technology

Introduction to ICT in Buildings and Infrastructure

The staggering influence of 21st Century Information and Communication Technology (ICT) and its creation of a service-economy are comparable to highlights of 20th century urban design such as steel and automobiles. Today the pervasive power of the internet has led to a Fourth Utility revolution wherein the internet is as indispensable as our core utilities for survival in this modern day and age. This, is being leveraged by Governments and private sectors to provide a greater quality of life using lesser resources thereby reducing the environmental footprint of our species.

Galaxy enabled smart city solution

Climate Change

One of the world’s most pressing challenges is climate change: the need to radically reduce greenhouse gas emissions, while continuing to enable economic development worldwide, is a combination that requires innovative action.

So far the Global leadership has been more of words than of concrete actions. Countries around the word have set targets to reduce impact on the environment and alleviate climate change effects. But, strong actions are needed to reach the targets that were discussed and set. Agencies from EU have reported that a maximum of 30% cut in GHG emissions by 2020 is imperative to hold the temperature rise under 2 °C, and a further 80% is required by 2050. Far reaching reductions further than the Kyoto targets can be achieved only by fundamental changes to our infrastructure, lifestyle and business practices.

As demonstrated in this document, there is a potential to allow the ICT sector to provide leadership.

This is a sector that is used to rapid changes and has many of the most innovative people in the business sector, and a unique service focus: it can become an important part of the solutions needed to combat climate change.

ICT has the potential to effect significant energy savings through smart use. Arduous logistics of travel and transportation is easily solved by ICT through shrinking distances and increasing efficiency. ICT allows a strategic shift to core services through economic de-materialization Above all it can reduce, manage and monitor energy consumption and carbon footprint of buildings and infrastructure.

Global Warming:

“Government, civil society and the private sector are encouraged to initiate actions, for sustainable production and consumption” –UNFCC and other Global Organizations like WWF, ETNO, WBCSD, CG and others have embarked on a joint initiative, “Saving the climate @ the speed of light”. This project rests on four assumptions: there is a need to act now, a strategy is necessary to ensure that ICT can combat to reduce CO2, there is a need for a clear focus and scale up those existing applications which are delivering good results. Three goals were chosen for the strategy in order to ensure the development of policy in the world that supported sustainable utilization of ICT services. The goals are meant to provide guidance for the work and provide a framework for the discussions with relevant decision makers in the world.

- ICT is recognized as an important part of the solution for combating climate change in the world.

- Key participants have a climate change strategy for ICT

- Concrete “ICT-Energy Services” programmes are initiated in the world to reduce, manage and monitor energy consumption and carbon footprint of buildings and infrastructure around the world.

The concrete cases provided in this document are based on existing and implemented ICT projects and solutions by Pacific Controls. They offer a new way for finding solutions, and show that: ICT Buildings Energy Services can be part of the solution.

The focus of Pacific Controls is to promote the ICT sector in playing an important role in reducing CO2 and scale up existing solutions and deploying an e-strategy for CO2 reductions. This strategy should include target based implementation of ICT services, and M2M technology in buildings and infrastructure.

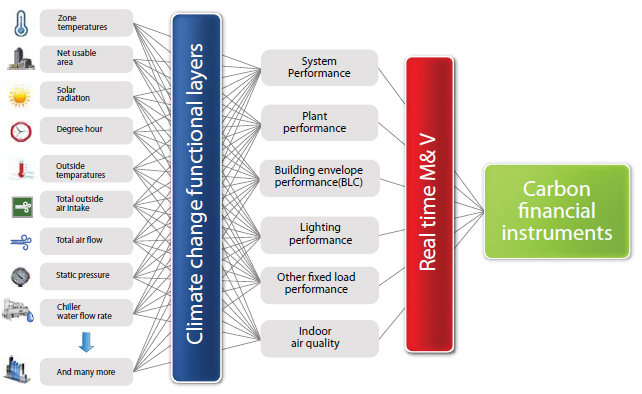

Measurement, verification, continuous commissioning and deployment of energy savings software to manage all energy consuming electro mechanical equipment in buildings to reduce energy consumption by 20 % to 30% and provide real time carbon footprint measurements of the targeted building or infrastructure is part of the ICT services. Pacific Controls look forward to working with other corporates who want to help ensure that the world gets an e-strategy for CO2 reductions. We are pleased that a number of corporates already have indicated their willingness to support these goals. We also look forward to working with different corporates to formulate more specific targets and strategies to help us achieve the goals. We will also start to work in parallel with the 2020 targets for an e-strategy. In this process we will broaden the scope and include other third party verified solutions and create a more comprehensive road map that can provide inspiration and guidance as well as serve as a benchmark for best practice. But most of all it will send a stronger signal to all relevant decision makers that the time for action is now. If the policy framework is right, ICT can become one of the major contributors to reduction of CO2 and a more resourceful and equitable society. The world faces serious environmental challenges and problems. Solutions to these are usually seen as being opposed to economic development. However, new technologies and knowledge can ensure that sustainable resource use and economic development is not only possible but mutually supportive. By approaching the challenges from a new perspective, problems can turn into opportunities: Pacific Controls has prepared the road map to support the major structural contributions where ICT and M2M Technologies can break the current emission trends in buildings and infrastructure:

Global Warming

The most recent results presented by climate scientists are alarming. The accumulation of greenhouse gases (GHG) in the atmosphere is growing faster than originally predicted. Scientists, economists and policy makers are calling for emissions targets of at least 20% below 1990 levels in 2020.

The most recent results presented by climate scientists are alarming. The accumulation of greenhouse gases (GHG) in the atmosphere is growing faster than originally predicted. Scientists, economists and policy makers are calling for emissions targets of at least 20% below 1990 levels in 2020. The scale of emission reductions that could be enabled by the smart integration of ICT into new ways of operating, living, working, learning and travelling makes the sector a key player in the fight against climate change, despite its own growing carbon footprint. No other sector can supply technology capabilities so integral to energy efficiency across such a range of other sectors or industries. But with this potential comes responsibility. Emissions reductions in other sectors will not simply present themselves; the ICT sector must demonstrate leadership on climate change and governments must provide the optimum regulatory context. This report outlines the key actions needed. These actions can be summarised as the SMART transformation. The challenge of climate change presents an opportunity for ICT to first standardise (S) how energy consumption and emissions information can be traced across different processes beyond the ICT sector’s own products and services. It can monitor (M) energy consumption and emissions across the economy in real time, providing the data needed to optimize for energy efficiency. Network tools can be developed that allow accountability (A) for energy consumption and emissions alongside other key business priorities.

This information can be used to rethink (R) how we should live, learn, play and work in a low carbon economy, initially by optimising efficiency, but also by providing viable low cost alternatives to high carbon activities. Although isolated efficiency gains do have an impact, ultimately it will be a platform -or a set of technologies and architectures -working coherently together, that will have the greatest impact. It is through this enabling platform that transformation (T) of the economy will occur, when standardisation, monitoring, accounting, optimisation and the business models that drive low carbon alternatives can be developed and diffused at scale across all sectors of the economy. The ICT sector can’t act in isolation if it is to seize the opportunity it has to tackle climate change. It will need the help of governments and other industries. Smart implementation of ICTs will require policy support including standards implementation, secure communication of information within and between sectors and financing for research and pilot projects. This report demonstrates the potential role the ICT sector could play in mitigating climate change. By implementing ICT enabled solutions and M2M technology. It is now up to policy makers, industry leaders and the sector itself to make sure this potential is realised.

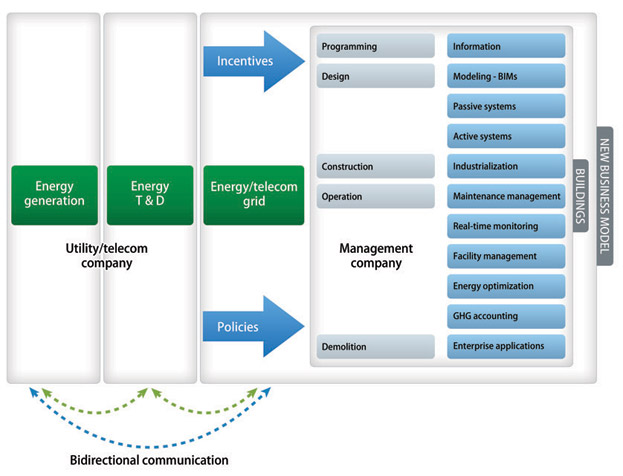

ICT for Energy Savings in Buildings

Information and Communication Technologies (ICT) have an important role to play in reducing the energy consumption and therefore increasing the efficiency of the economy, in other words, in reducing emissions and contributing to sustainable growth. Indeed emerging changes offer the possibility of modernizing the global economy, towards a future where technology and society will be attuned to new needs where innovation will create solutions using ICT to reduce energy consumption in buildings around the world.

ICT will improve energy efficiency and help combat climate change, it will also stimulate the development of large leading edge market for ICT enabled energy efficiency technologies that will foster the competitiveness of global industry and create new approaches in measurement, verification of carbon footprint in real time. As ICT is today pervasive to all industrial and business domains, it is expected to generate a great impact in the energy efficiency of new and existing buildings. Pacific Controls focuses on delivering ICT solutions for energy services in new and existing buildings. The focus is on the building itself, including equipments and devices, the envelope, and the potential connection with the ecosystem (e.g. electric grids, Global Command Control Centers for energy services). It also includes considerations from an urban point of view. It is clear that, if the world is to succeed and achieve its ambitious objectives, the role of ICT as an enabler of energy efficiency across the economy needs to be fully explored and exploited.

The World Needs to ensure that ICT Enabled Solutions will be:

Available: in addition to developing the necessary individual components, more has to be done in terms of system integration and development of software and hardware that’s open and seamless for providing energy services in real time.

Fully deployed: this means deployments in large infrastructure projects with the objective of carrying out assessment obtaining feedback and creating bench marks for further deployment in the built environment Operational: Show casing the potential of ICT enabled solutions installed and perfectly operating, and the impact of these systems on the social environment enabling people to be able to “work/live with them”.

In order to put ICT at the core of the energy efficiency effort and to enable it to reach its full potential, Pacific Controls have initiated research and development into ICT-based solutions and launched campaigns to strengthen and accelerate the adoption process by engineers, consultants, architects, planners government departments and developers, so that the energy consumption impact of the economy can be further reduced by adding intelligence to components, equipment and services.

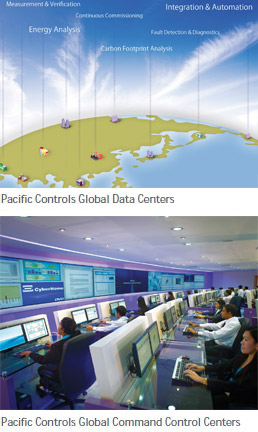

Pacific Controls have pioneered ICT solutions in the energy services and the building domain, delivering large scale solutions of energy / building management system for public and commercial buildings, and has established the worlds first Global Command Control Centers (GCCC) for energy services, facilities management, real time measurement & verification of carbon footprint of buildings, delivering real time carbon financial instruments using ICT solutions.

The GCCC are state of the art facilities established in different continents of the world, using unique ICT based software and hardware for real time management of the energy eco system.

According to global statistics buildings consume more than 40% of the energy produced in the world. This is due to heating, cooling and lighting operations within buildings. Buildings are the largest source of CO2 emissions (including their electric power consumption), and their total energy consumption has been rising since 1990. As such, developers need to deal with new challenges including addressing construction from the viewpoint of sustainable development, energy efficiency and decrease of GHG emissions, improved innovation in the built environment for better comfort and safety.

The cross-fertilization of buildings and ICT (with new innovative ICT architectures and tools integrated in the built environment) has to deal with the key following expectations:

1) the generalization of “energy-positive smart buildings”. Energy-positive buildings are transforming buildings from pure consumers to “presume” (producers and consumers). Smart buildings means buildings empowered by ICT in the context of the merging Ubiquitous Computing and the Internet of Things: the generalization in instrumenting buildings with sensors, actuators, micro-chips, micro- and nano embedded systems will allow to collect, filter and produce more and more information locally, to be further consolidated and managed globally according to business functions and services (Machine to Machine –M2M)

2) Buildings will play a new and key role in innovative distributed energy production, and new associated business models, for renewable energy management, storage and peak shaving: they are to move from “end of pipe” buildings to active nodes in smart grids. They will permit to optimize the local distributed production and storage of energy/electricity, to deal with shaving consumption peaks and the optimization of energy consumption, to deal with the management of local coordination of the energetic system, while at the same time ensuring appropriate integration with smart energy grids - including securing the provision at any time of the energy (where ever it comes from - local or global), all this in a systemic approach and according to some various contexts (user profiling, security level, etc.).

3) The development of interoperable business applications and services (especially atop BIM’s – Building Information Models), to deal with enhanced diagnostic and renovation of existing buildings and infrastructures and simulations to assess variants of environmental performance of buildings, tools for dynamic building evaluation at run-time, and allowing optimization based on multi-dimensions / multi-criteria constraints, etc.;

4) The required need to deal with the increasing volume and complexity of all the information generated by the systems mentioned in the previous points, potentially coupled whenever required with the huge mass of information over the Internet, and also to deal with knowledge that is already available but not easily accessible: tools already exist in this area and Pacific Controls have developed software and hardware to consolidate data and deliver them to the enterprise at the GCCC.

5) A final key point is construction stakeholders and users awareness, to be achieved through innovative, pervasive and friendly user interfaces. User awareness is a key factor for moving to eco-friendly behavior. However, very few building owners know what consumes the most energy in their building(s) and even fewer look regularly and accurately at the energy meter attached to their building since it remains an uneasy and tedious task. Pacific Controls have delivered user interfaces/energy-displays that provides attractive content at the appropriated time to asset owners and service personal, delivering this service to the end user using pervasive internet.

Energy Efficient Buildings

Energy Efficient Buildings construction is one of worlds biggest industries providing building and infrastructure on which all sectors of the economy depend. Construction, operation and maintenance of facilities is about 20% of GNP in industrialized countries and life cycle costs are dominated by operation and maintenance while design & construction are less than 25%. Efficiency in buildings has been identified as the main challenge for the coming years since it is well known that buildings are the largest source of CO2 emissions.

In order to address this strategic topic, the construction model must evolve towards a new multidisciplinary approach which will empower the scope and impact of future developments, improving cooperation with ICT, energy and other sectors. This is a big responsibility. This cross-sectoral initiative could really contribute in a significant way to the fight against climate change issues, in addition to decreasing the worlds fossil fuel dependence. Pacific Controls has developed ICT tools which will enable significant energy consumption reductions at an early stage, to the building operation phase, where, as an example, advanced metering infrastructure could provide the framework for joint business models among energy utilities, telecom operators and building management companies.

The potential to reduce the world’s energy consumption by focusing on the commercial building sector is tremendous. Governments and businesses need to quickly focus on making commercial buildings “smarter”. Building owners and operators have been generally slow to adopt practices that could improve their energy efficiencies.

This is due to many factors, including a lack of incentives for owners, insufficient demand from tenants, and the expense associated with retrofitting legacy systems. The inability to centralize and manage data found within building equipment is a challenge. Existing commercial buildings are full of technology and communication devices that have been installed ad hoc over time. These technologies which include security devices, computer/Internet connections, heating and cooling systems, and lighting tend to operate on different protocol standards. In this non-integrated, multi protocol environment, monitoring energy usage and device performance is perceived to be difficult. Pacific Controls have developed and implemented cost effective software hardware solutions addressing this very challenge to seamlessly integrate disparate systems delivering totally integrated solutions without assigning dedicated personals or team typically assigned to monitor or use building data to drive building management efficiencies using M2M and ICT systems.

Pacific Controls have delivered solutions to digitize buildings and make it possible for devices to work together more effectively and reduce energy consumption. Pacific Controls has also established GCCC where multiple number of buildings in a city are managed through a web interface where building operators stay connected and pull data out of every set point at desired intervals. This gives a constant stream of data to understand how the building is operating and how it can be run more efficiently. In short, our solutions make buildings smarter on a continuous basis. It’s proven to be a cost-effective solution with 25% efficiency gains in less than one year.

Smart Buildings

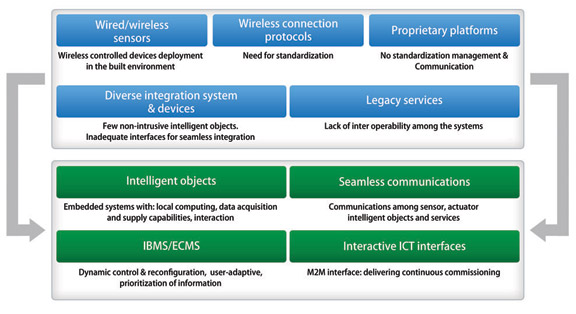

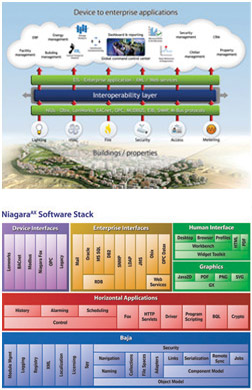

Pacific Controls uses devices like sensors, meters and intelligent objects based on open protocols that are standardized and open to communicate among them and with services over the network. The “smart BMS / ECMS is relying on embedded intelligent objects and communications.

ICT-Eco System for Energy Efficient Buildings

MANUFACTURING: Improvements of the production of building materials and integration of the supply chain reduce embodied energy in buildings. In particular steel, concrete/cement, bricks and glass require very high temperatures that can only be reached today by the burning of fossil fuels. It is considered that today about 10% of all CO2 emissions globally come from the production of building materials.

LOGISTICS: It is considered that 15% of whole CO2 emissions during the construction process is due to the lack of a smart logistics approach. Tools for effective logistics planning and management from suppliers to site and ambient/embedded guidance for on-site assembly work are widely deployed in construction sites. This also ensures the optimization of resource management and quality control.

KNOWLEDGE SHARING: There will be a capability to support the sharing of Energy Efficiency related previous experiences, best practices and knowledge within and, increasingly between organizations from ICT, energy and construction sectors. The aim is to have seamless connectivity to the right information, at the right time, in the right format, and from the right sources, both internal and external. Open knowledge sharing among all stake holders globally will enable an improvement on cross-sectoral joint cooperation.

COLLABORATION SUPPORT:Collaboration environments where project partners are connected in a transparent way are easy to use without system specific training. These kinds of tools will enable collaborative design and construction processes shared by architects, engineers and even clients. Entering this virtual working environment, the architect could control the energy efficient design, the engineer could assess the timetable and the building-costs and the client could choose among different solutions at an early stage.

AUTOMATION AND CONTROL SYSTEMS: Pacific Controls provides modular, easily customizable with configuration tools, advanced ICT solutions for buildings considering their behavior, performance, external environment and their user’s needs. Applying Pacific Controls ICT solutions for control systems and home automation has already made an impact on energy demand at the level of households and much more at the level of publicly owned buildings which are professionally managed. Pacific Controls integrated building control systems has enabled the integrated interaction of a number of technological elements such as heating, ventilation, air conditioning, lighting, safety equipment etc. The embedding of ambient intelligence in building, sensors, wireless communications and data processing has contributed to better temperature management, leading to reduced energy consumption.

SMART METERING: Pacific Controls smart metering systems enable individual users to see their consumption pattern and adopt appropriate measures for energy saving. Pacific Controls is also developing bi-directional communication capabilities enabling utility companies to perform demand-side management in order to reduce energy peaks risks as well as energy production costs.

USER-AWARENESS TOOLS: Pacific Controls has thousands of home automation systems installed in various developments. There is continuous interaction and intuitive feedback to users on real time energy consumption in order to change behavior on energy intensive systems usage, reducing 5-15% of energy consumption. In addition, human-centric graphical user interfaces developed by Pacific Controls ensures the acceptance of embedded systems and other ICT-based solutions. Users do not get bombarded by a barrage of feedback data about something that they do not require in the first place: information provided by the system is unobtrusive, and attuned to the user’s available attention, taking into account both his/her activity and the urgency of the notified information.

BUILDING AND NEIGHBOUR- HOOD MANAGEMENT: Pacific Controls have developed intelligent management systems inside buildings and has shown that important energy savings can be reached using these technologies. The use of these intelligent systems inside buildings can improve the control and management of heating, ventilation, air conditioning, lighting, and other energy hungry devices. However, buildings are not energy-hungry systems any more.

AMBIENT INTELLIGENCE / CONTEXTBASED SYSTEM USAGE: Spaces can detect user presence and personalize the environment to the user’s preferences: lighting, temperature, indoor air quality etc. The user’s identity is protected.

STANDARDS: Today, most control systems are based on micro-processor technology. Sensors, for determination of temperature or flow rates, are typically connected to the control system by wires. There are algorithms implemented in the control system strategies. The most significant weakness of current control systems is that, in most cases, separate controllers are used for each application. For instance, there are often separate controllers for solar thermal, space heating and cooling, lighting and air-conditioning systems. Typically, the individual controllers operate separately, without exchanging information and, as a consequence, the building is not considered and controlled as one single system, but as a number of individual sub-systems. This leads to sub-optimal results in terms of energy flow, comfort, cost and controllability. The most appropriate solution will be interoperable control systems, governing all HVAC, and lighting other electrical applications, and related sub-systems installed in a building.

INTEROPERABILITY: Pacific Controls uses common ontology, open interfaces and communication protocols providing interoperability between various ICT tools and systems in a seamless way. Interoperability may indeed be examined according to two different foci that indeed share common specificities: The first one is related to interoperability as defined in the “Building SMART” Alliance: interoperability is to support an ICT-based (automated) global environment where all participants (owners, operators, designers, constructors, regulators and other stakeholders) can readily and transparently share, communicate, apply and maintain information about facilities and infrastructures around a Building Information Model (BIM), that is a unified data resource system that makes accuracy, speed and economy in building design, construction, and facility operations possible. In order to do it quickly, efficiently and safely, especially avoiding ambiguities, the concept is related to the one of open standards. The second one is related to smart homes and buildings increasingly relying on all types of consumer electronics and embedded systems, targeting a goal of comfort and efficiency that can be reached through the convergence of consumer electronics appliances, communicating devices and applications/services in homes. This second point obviously links with interoperability technologies and tools to achieve embedded intelligence: interoperability will allow devices and applications in smart homes and buildings to collaborate and provide consumers with greater flexibility in selecting their desired services, and will support the potential cooperation between constructions; energy and ICT based services companies. Management information systems require, detailed analysis of potential impacts of ICT-based solutions on energy efficiency is needed as well as the creation of energy saving business models supported by ICT. Local building energy profiling will have a definitive impact on the way energy is generated and distributed moving the building from a demand side to a “prosumer” (producer consumer) profile. Pacific Controls has launched a series of innovative building technology products and smart devices: dealing with more energy efficient space heating, HVAC equipments, elevators, water boilers, appliances, white goods, etc. Transparency creating products: educating energy end users about the impact of their choices and behaviors on their energy consumption and therefore encouraging more conscious use of energy. These devices include smart meters and graphic user interfaces or dash boards at the consumer’s location.

REMOTE OPERATIONAL SERVICES: Global Command Control Center for energy services, an area where Pacific Controls plays an important role in the end-to-end delivery of smart building applications, targeting both the end-user and the utility provider. To the end-user Pacific Controls is able to offer energy efficiency applications using multimodal interactive interfaces (TV, PC, mobile phone...), e.g. smart metering details, per appliance real time power consumption, temperature monitoring, etc. To the utility company, Pacific Controls can offer smart metering services. In addition, Pacific Controls enables maintenance of the BMS, and other services like remote monitoring, surveillance and management/control of appliances, facilities management information, real time carbon foot print measurements and carbon financial instruments. Pacific Controls has already pioneered in ICT services empowering the worlds most modern university (King Abdullah University of Science & Technology, Saudi Arabia, KAUST), worlds most modern airport (Dubai Airport), National life safety project for Govt of Dubai, National energy services projects, large city developments (MEYDAN), large commercial developments (CISCO Headquarters-Dubai, Pacific Controls Head Quarters-Dubai), large residential developments, individual building owners, data center owners and home owners to remotely manage and optimize their operations delivering energy efficiency and savings in real time. The system also enables technicians to manage many buildings from a central location thereby achieving scale and energy efficiencies using Pacific Controls GCCC to play an important role in providing secure remote access to smart homes, buildings and infrastructure from a countrywide and global perspective.

Pacific Controls delivers the services of an Energy Services Company (ESCO) offering a wide range of services to energy users, including operation and maintenance of installations, facility management, energy management, energy audits, demand monitoring and management, measurement of carbon foot print and validating carbon financial instruments in real time through the Pacific Controls

GCCC LIGHTING & PHOTONIC: It is considered that about 12% of energy consumption in buildings is due to lighting. This figure increases in the non residential building sector. Pacific Controls is already offering Smart integration of new lighting technology (high performance technology) and devices (e.g. intelligent LED solutions) in Smart Buildings. RE-STRUCTRING: New business cases and new (ICT-based) business models Establishment of common (integrated) platform for measuring and informing citizens, service providers and organizations about the carbon footprint of all activities of, e.g. a city’s life. Pacific Controls offers cost-effective deployment of specific ubiquitous ICT systems along with the seamless adaptation of moving environment context, e.g. adding or removing resources; Incorporation of the human dimension (for instance, needs from the end-users) in ICT, especially through solutions that are “accepted” by the user, e.g. with systems naturally interacting with the user, with systems having the capacity to learn and adapt themselves to the way of living or working, with dynamic adaptability to the user specificity (handicap, health, age,), etc. overall issues related to human activity and energy efficiency, and to the design of interfaces accordingly; Adaptation to the user’s instantaneous activity, situation and context; Understanding and development of quantitative tools that match reality; Scaled and selective mining, as well as visualization, of D/I within large databases, along with integration of disparate databases; Development of mature cross-domain / multi-disciplinary software tools and ICT based services for industry; Development of formal models for performance metrics for sustainability and energy-efficiency in buildings and urban areas.

Energy Services for Buildings

Buildings are one of the biggest energy consumers in the world, accounting for 40% to 50% of all energy used and a similar amount of greenhouse gas emissions. Whilst cars had to meet increasingly strict fuel efficiency standards, buildings for the most part have gotten off easy. Surprisingly little attention has been paid to ensuring energy efficiency in buildings, despite the tremendous impact buildings have on costs and the environment.

This oversight is starting to be addressed. A combination of higher energy prices, skyrocketing demand for electricity and deepening environmental concerns has pushed the world to a tipping point with regard to energy efficiency in buildings. Business as usual threatens worlds continued prosperity. As an example of the changes that are occurring, the Clinton Foundation recently announced an unprecedented initiative to funnel up to US$5 billion in loans from some of the world’s largest banks to fund building retrofit projects that increase energy efficiency. Asian Development Bank, World Bank and some Governments have offered similar funding to increase energy efficiency in buildings.

The advent of ICT enabled energy services solutions have revolutionized the deployment process. The economics are powerful, promising quick paybacks on investments for building developers and their tenants. The economic case is equally strong for governments, which are furiously building power plants in an attempt to keep up with surging demand from new and existing buildings and their often inefficiently managed HVAC (Heating, ventilation & air-conditioning systems), other building services systems including lifts, pumping systems, hot water systems and lighting systems. Pacific Controls have pioneered the deployment of ICT enabled energy services globally and have established the world’s first energy services Global Command Control Center offering 24x7x365 days managed energy services to building owners globally, delivering substantial energy efficiency.

Greater efficiency means consumers can enjoy the same level of comfort but use less energy. And when it comes to efficiency, improvements in buildings offer the most cost-effective way to reduce energy use and greenhouse gas emissions. The McKinsey Global Institute, which has studied the issue on a worldwide basis, estimates that four of the five most cost-effective measures taken to reduce greenhouse-gas emissions involve building efficiency. Incredibly, these measures result in net savings for building owners and their tenants, because the cost of improvements is so cheap compared to the savings.

Remotely Managed Energy and Facilities Management Services for Buildings and Infrastructure

Pacific Controls offers end to end platform that proactively monitors facilities such as commercial buildings, educational Institutions, banks and financial institutions, government service Infrastructure like airports, ports and railway infrastructure, residential buildings, data centers industrial facilities, telecom infrastructure and power distribution network. This platform provides unambiguous transparency into how the facility performs, where critical faults lie, and where opportunities exist to significantly reduce operational expenses. This groundbreaking communications architecture further enables integration with existing enterprise business and ICT processes, such as integration into ITIL/ITSM programs and infrastructure. This robust M2M communications and automation platform can easily be tailored and expanded to manage and report any number of facility infrastructure assets from any standards compliant manufacturer. Our modular approach, built on a proven architecture, enables intelligence across power generation and distribution, cooling and chiller equipment, lighting and environmental systems, water and waste systems, physical building security systems, and other facility subsystems.

Advantages of our Modular Approach

Our core advantages:

- Energy auditing and management, including energy monitoring, energy conservation analysis, carbon footprint analysis, and performance analysis

- Facility infrastructure monitoring, predictive fault analysis, and root cause analysis

- Active management and application of logic within and across facility subsystems

- Industrial automation

- Enterprise systems integration

- Online Java based interactive reporting systems that provide real time and trend based information to drive effective decision making

Pacific Controls offers complete facility management and monitoring solution that optimizes performance, drives the reduction of energy consumption and cost, increases systems efficiency, and helps to significantly improve facility end user satisfaction. Our facility monitoring solutions help to proactively resolve impending problems and enhance business operations. These solutions enable monitoring that informs the business about the status of their facilities and their subsystems, providing an ability to address problems before they arise.

Our approach includes

- Predictive analysis: receive information and root cause analysis of impending failures so that unplanned outages are avoided

- Consumption planning: monitoring enables proactive notification on facility systems consumables renewal, such as fuel refills, reducing risk and reducing costs through logistics and supply chain efficiencies

- Business intelligence: real time information helps drive better systems utilization, alignment between facility and business needs, and Predictive analysis critical information that drives the business cases necessary to take actions to drive out operational costs with minimal capital expenditures

- Our value proposition is based on providing customers with next generation facilities infrastructure monitoring and reporting using Pacific Controls cloud computing and virtualization platform.

These managed solutions offer customers key advantages, including:

- multi service platform allowing customers to subscribe only to the services they need and add new services as needs change or as new services become available.

- encrypted and secure services are provided, with the option for local hosting if necessary.

- delivery model provides the best possible 24/7 remote infrastructure monitoring and reporting support, with regional offices in North America, Europe, Middle East, Asia Pacific and Australia.

- managed and professional services enabling facilities security lifecycle from assessment, policy management, device monitoring, change management, incident response, through auditing. Once registered, the solution can be used for real time data acquisition, monitoring, and control of managed infrastructure devices though the private GPRS cloud, or via P2P tunnel.

Benefits of Remote Buildings and Infrastructure Monitoring

- Designed to work across distinct asset classes

- Easy to configure and can be used with fixed and mobile assets

- Cost effective means to monitor individual infrastructure components or whole sites, even whole cities

- Reduced onsite management complexity, costs

- Rapid event response and single point of contact (SPOC) services

- Usage analysis for maintenance optimization and consumables replenishment

- Reduced energy consumption and operational costs

- Increased infrastructure productivity and extended lifecycle

- seamlessly integrated into standardized ICT and business processes and systems

Remotely Managed Energy and Facilities Management Services and Infrastructure: Measurement & Verification

Remote monitoring and management is rapidly becoming an integral part of facility management services globally. Conventional methods of management, where data logging and equipment registers are maintained and reactively reviewed, are obsolete and ineffective. Under our state of the art automated management framework, we apply deep analytics to the review of streams of logs and performance data from infrastructure devices. This logic, akin to data mining and profiling, provides deep insight and intelligence into the real time and trended performance and capabilities of infrastructure assets.

Traditional manual processes rely on site visits, costly maintenance programs, and in best case scenarios, failure notifications from dedicated software or devices, or BMS platform. This traditional approach does not provide any proactive insight into asset performance, Power distribuition unitsor provide individual or aggregate guidance on the energy consumption and capabilities of the facility. Without this information, it is difficult to impossible to determine if the facility and its infrastructure components are performing to their intended level, are cost ineffective, or where there are opportunities for improvements that drive down operational costs.

Even more challenging in the traditional approach is the lack of any efficient method to apply performance and consumption benchmarks, or to compare current performance against a measured baseline. Thus, how would one know when or if infrastructure performance is degraded or there is a need to consider the cost efficacy for equipment replacement.

Our solution provides the means to easily and properly understand the scale of any problems and opportunities through the establishment of benchmarks, baselines, and performance and consumption metrics and targets. Valid trending analysis requires extensive ongoing capture and analysis of data from infrastructure assets, which is a core strength of our solution.

Measurement and Verification Services (M&V) for facilities is a field of energy engineering that typically provides consulting on projects after their completion to provide third-party verification of actual performance. These services can also be applied as energy auditing, which provides regular recommendation reports to justify upgrades and infrastructure changes.

Our M&V solution provides a central repository for metering and performance data collected through a network of meters, sensors, smart devices, and bus interface units. These devices can provide real-time data on the actual state of the device, but also other data such as temperature, humidity, air/fluid flow, telematics, and other applicable attributes. This network of intelligent devices provides the basis for real time and trend analysis of Power Usage, performance effectiveness against laid down benchmarks. Our intelligent platform is designed to enable economization methods to drive down power usage and increase efficiencies such as managing temperature, dew points, and airside/waterside economization equipment to achieve the best performance consumption balance.

Our Delivery Approach

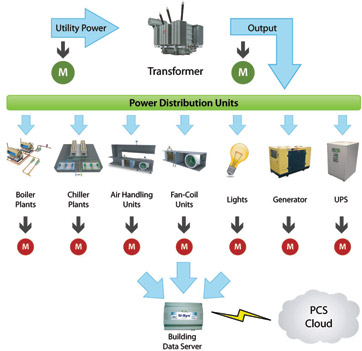

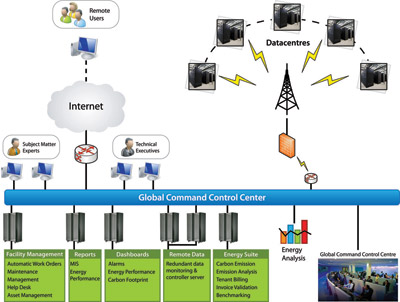

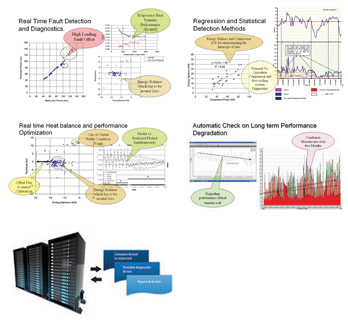

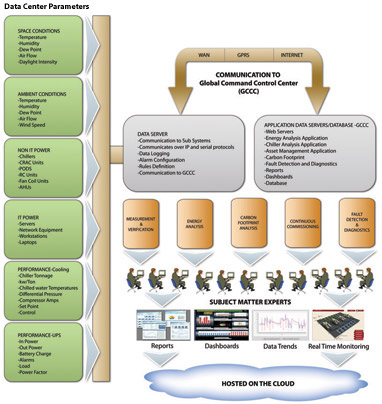

While there are several methods for delivering these capabilities, Pacific Controls approach has proven exceedingly effective in the monitoring and management of facilities. Figure 1, below, provides a visual representation of the architecture of our solution, implemented at facility level.

Energy Monitoring at the Facility Level

While there are several methods for delivering these capabilities, Pacific Controls approach has proven exceedingly effective in the monitoring and management of facilities. Figure 1, below, provides a visual representation of the architecture of our solution, implemented at facility level.

Our solution monitors power quality and consumption at each and every level. We either install our digital multifunction energy meters, or integrate into existing metering systems via industry standard open and legacy protocols.

We describe below the levels of monitoring and management we apply:

Level 1: Utility Power The utility and transformer output power are measured and monitored. This provides a clear indication of transformer efficiency and loss, and also provides a baseline for building entry power.

Level 2: Cooling and Lighting The power consumed by cooling equipment – from chillers through air handlers and closely coupled cooling equipment – is measured to understand consumption patterns.

Level 3: Power Systems The power input into the UPS and other distribution systems and corresponding outputs are measured using high accuracy meters and/or through integration into the UPS’s management system via standard protocols. The above methods help to provide key efficiency and consumption figures for protected power distribution. Further granularity – down to the building level is possible through the deployment of sets of inexpensive sensors and meters at key points in the power distribution chain. These meters and systems directly communicate with the data servers. These servers provide multi-protocol engines that provide several key functions such as data logging, alarm notification, and a control engine that provides enforcement of use cases and controls. Performance data is logged on a regular basis with the granularity determined by customer needs. Logging activities are, in all cases, redundant in case of any single failure.

The Central System:

Figure 2, below, provides a view of the overall architecture on how a facility is connected to the central system.

Data collected at the building assets facility level is updated to the central repository on a regular basis. The Global Command Control Center (GCCC) provides enterprise level tools and software solutions that provide the essential monitoring and verification services. These services are supported by subject matter experts (SMEs) who have extensive experience in the service and support of HVAC, electrical, and energy systems.

The GCCC is also responsible for the 24/7 monitoring of all managed building assets. This includes all proactive maintenance notifications, fault management, SPOC services (including, when required, dispatch and management of local service personnel to resolve issues or to perform maintenance), and reporting. Our applications continuously benchmark infrastructure performance, helping to ensure that desired metrics are met. We go beyond mere monitoring to actively provide deep diagnostic analysis, which drives improvements to desired and achievable energy performance levels.

In addition to monitoring energy consumption and performance, we also actively monitor and report against other measurable factors – such as temperature, dew point, air and water flow. This additional analysis drives active automated decisions on changes to settings that improves performance and drives down consumption – even across a heterogeneous environment where equipment is from multiple vendors. Our platform enables intelligence across platforms when traditionally they could not be integrated.

The Deliverables:

The major deliverables of our M&V services include:

1. Real time monitoring

Our systems are web-based and can be accessed via standard web browsers from a wide range of devices, including mobile devices for some interfaces. There is no additional software required to be installed on any client system. Data is provided in a logical and easy to understand graphical format.

2. Data trending Included in the real time monitoring interface are key data trends. users can access these real time trends, identify the important operating parameters such as temperatures of water & steam,water & steam pressures, % of oxygen and % of carbon dioxide (CO2) in flue gas and flow of fuel, steam and water. These critical parameters trend gives idea about the performance of the equipment. It also allows users to select any number of single and multiple points which can be trended together. Users can access these real time trend reports, identify important data profiles, and view performance issues. The trends interface allows users to select any number of single and multiple points to be mapped against each other.

3. Monthly reports Our advisory services provide a monthly report that details monitoring and diagnostic results. This report also gives the reader a set of recommendations for investments to the infrastructure that would typically reduce operating expenses.

Remotely Managed Energy and Facilities Management Services For Buildings and Infrastructure: Energy Analysis

A key element of the offering is energy analysis. Logging activities against energy consumption data provides a set of profiles that can be further analyzed and can be acted against. Ongoing tracking provides the application of the best set of solutions to consumption goals and challenges.

Smart monitoring is an approach where the tracking of energy consumption data provides the information necessary to apply an effective energy consumption reduction strategy. This knowledge and awareness enables control and application of the strategy, with results tracked in real time. Utilities management can occur rapidly – no need to wait for monthly energy bills, reports, and other legacy data. To achieve this capability, rigorous intelligence gathering is required at every point in an organization’s infrastructure where energy is consumed. In the case of assets facilities, for instance, each cooling device requires monitoring and management – from its own available intelligence layer to independent sensors. Being able to leap from simple reporting to actionable data also requires that the sensors be queried for their data on a granular basis. This increased level of detail is invaluable in understanding the effects on utility consumption from changes to the environment, cooling, lighting, and other systems. Granularity drives the ability to form correlations, which in turn drive use cases, metrics, and targets. Thus, the information derived from this process empowers management to make decisions, which can demonstrably reduce the cost of operating the assets. In all of these applications, smart devices specific to the context generate a data stream that is communicated back to a central collection and analysis point.

Figure below, highlights the process of data monitoring, collection, analysis, and delivery. Each facility management service that we offer Global Command Control Centerfollows the same general process.

This block diagram shows how end to end services are provided – from field device installation, though enterprise level integration. Here, we show the interconnection of key monitoring perimeters, such as environmental and power performance characteristics. We describe the flow in more detail below:

1. At the customer site, devices are connected via standard protocols over wired or wireless networks to a central management system.

2. When sensors are not in place, we install and commission sets of sensors to deliver the requested level of detail and capability.

3. The management system monitors devices in real time, and also ensure control of managed perimeters.

4. The management system also:

a. Communicates to the central repository for aggregation and reporting

b. Stores data locally to protect against upstream outages

c. Serves as an alarm engine, where alarms are stored and acted upon locally. Alarms are aggregated and further acted upon at the central repository level

d. Serves as a rules engine, where rules (use cases, systems integration) are applied locally, and rules are aggregated and further acted upon at the central repository level

5. At the GCCC/repository level, additional applications and SMEs transform the information, alarms, and rules results into knowledge and advisories. Additional GCCC interface components include:

a. Energy analysis suite

b. Chiller analysis and management suite

c. Operations manager

d. Fault detection and diagnostics tools

e. SME repositories

6. Earlier resources and information are core components provided as advisory services and are provided through the “cloud”

7. Core output deliverables include:

a. Reports

b. Dashboards

c. Data trending

d. Real time monitoring

e. Alarm management and monitoring

8. Deliverables and services are available

on Internet via secure connections,

and can be accessed via any point in the world.

The Deliverables:

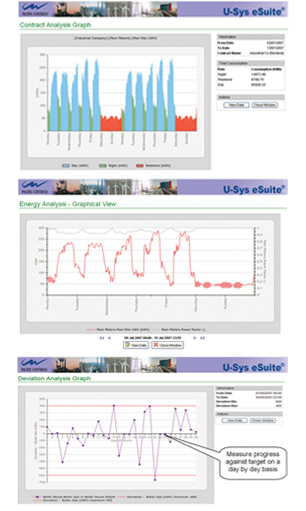

The use of dedicated energy management software gives us power of systems energy, cost and carbon related understanding. We use enterprise energy management software, which have capabilities of integration with the existing frame work with ease and gives us flexibility of using and exploiting the power of its independent calculation modules. This includes energy budgeting and targeting, energy analysis, financial analysis, reporting, benchmarking, invoice validation, tenant billing, contract bid management and emission trading. Perform comprehensive analysis of energy data including degree day, base load, regression, electricity analysis and league tables based on different key performance indicators. Our energy analysis service portfolio goes beyond monitoring to actually provide diagnostics and analysis to improve and maintain desired energy performance. The major features that we provide are

I. Energy Analysis:

The Energy analysis allows data to be presented in a wide range of graphs and tables. Consumption analysis form electrical and gaseous sources will be conducted. Consumption analysis of fuel, water, heat and electrical sources will be conducted. Track and trend changes in energy usage over time. Combine current power utilization and costs to the optimal configurations. The real time trends information of various energy usages & losses helps to cost analysis, present operation scenarios and analysis of bench mark. Obtain information needed to qualify for power company or government rebates and incentives. This leads to cost optimization.

II. Benchmark Analysis:

This feature allows facilities to be benchmarked against targets established by the application of local and international standards. The output of this analysis includes recommendations that, when applied, can result to better alignment with targets, and associated cost reductions. Progress can be measured as often as daily.

III. Performance Analysis:

Performance analysis allows comparison of consumption data with production data or degree day values, comparison of boiler thermal

efficiencies analysis, air/ fuel ratio analysis evaporation rate analysis, derived from direct and indirect method. For example, regression analysis, CUSUM analysis and deviation analysis are a part of performance analysis Through the regression analysis we can identify the relation between the IT loads and the cooling units such as the CRAC and PODs. This will help identify operational effectiveness of the cooling system as well as fine tune systems for optimized performance.

IV. Financial Analysis:

Financial Analysis helps in

- drive operational cost savings with verifiable results

- justify budget requests with indisputable operational data

- extend equipment life by improving operations

- create a positive cash flow

V. Base Load Analysis:

Base load analysis will provide analysis between Base load and Active load separately. We use base load analysis to understand if energy is being used outside of the operating period or occupancy time. Identify when energy is used most and if unnecessary energy is being used during off peak hours. Drill down to understand the unusual energy usage and suggest recommendations.

VI. Base Parameter Analysis (Boilers):

Base parameters analysis will provide analysis between base operating parameters, data of boiler temperature, air flow, water flow, fuel and electricity consumption and actual data separately. This base parameters analysis helps to understand how much heat, water & electricity is used outside of normal operating loads or occupancy periods, it highlights when energy is consumed more. This will help the operator to understand the flow & consumption pattern of various energy sources, gives the idea about the possibilities of energy conservation and savings.

VII. Reports:

VIII. Dashboards:

We have dashboards for different type of users and hence they have different profiles. The Dashboards are a combination of historical and real time data and provides a single window information of the entire assets. Our Dashboards are very intensive in the sense that they have the capability to drill down right from yearly data to detailed data that’s collected every 30 minutes. An user can view data across parameters and systems and easily retrieve previously viewed data at the click of a button.

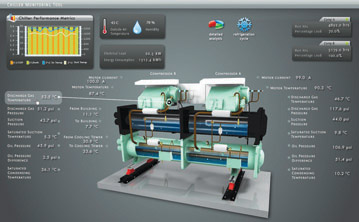

IX. Chiller Analysis:

Chilled water-based cooling systems are frequently used to air-condition large office buildings or campuses that encompass multiple buildings. They represent a large investment from the perspective of initial cost, physical space they occupy within the building, as well as energy and maintenance cost. Yet despite these fiscal and spatial impacts, many chiller plants do not reach their potential from the standpoint of energy efficiency. The development was targeted to address the need of medium to large chilled water plants such as Assets, hospitals, shopping malls and district cooling plants for handy and online performance assessment as well as effective reporting

mechanism for maintaining the plant as close to the benchmark as possible.

Energy performance of a chilled water plant is an important aspect to talk about, if we talk about saving energy in building operation. As cooling generally constitute about 60% of the total load of the building, managing and tracking the chilled water system strategically pay off in huge saving with little investments. The chiller tool has a web based and flexible frame work which is capable of communicating with large variety of plants and its equipments, and performs various integrated expert data mining and analysis to deliver important efficiency and diagnostic information to the user. The chiller tool frame work is broadly expected to deliver following functionalities to the user.

- Performance metrics calculation

- Data acquisition and archiving in a reliable database.

- Data visualization and reporting.

- Control chilled water temperature (in cooling coils for air conditioning) to reduce energy use

- Turn off loads like chiller and chilled water pumps when not required

- Control variable speed drives to reduce chilled water pump energy

- Turn off lights and lifts when not in use

- Receive data from the peripheral controls, such as occupancy sensors, and relay this information to the system control level

- Allow the use of economy cycles using outside air

- Optimum start

- Night purge

- Economy cycle

- Ventilation control

There are two kind of calculation which is expected from the framework. These are primary and secondary calculation. Primary calculation constitutes the first hand treatment of incoming data within the hardware itself. Parameters from the chiller like chilled water inlet and outlet temperature, condenser water inlet and outlet temperature, chilled water and condenser water flow rate, etc are logged and treated via soft coded algorithms in the hardware. The purpose of residing these calculations on the hardware is to make sure that the data base which is then populated from these values has all the necessary data to perform secondary and more advance calculation.

The secondary calculation routine will be considered as brain of the software. This calculation class includes various subroutines like DOE grey box modeling approach, integrated part load value (IPLV) and drift identification techniques in statistics.

A. DOE Grey Box Model Approach

The second curve describes how the full load efficiency, defined as power consumption in kW per ton of cooling varies with water temperatures. This is also a dimensionless term. The third curve describes how the power consumption varies at part load conditions. This is again a dimensionless term.

B. Integrated Part Load Value (IPLV)

Integrated Part-Load Value (IPLV) is a single number part-load efficiency figure of merit calculated as per the method described in ARI standards 550.590 (2003) Standard Rating Conditions. A single number part-load efficiency figure of merit calculated as per the method described in this standard referenced to conditions other than IPLV conditions.

C. Drift and Clustering Analysis

The matrices and figures which come out of monitoring and measurement for a specified period of time are some time irrelevant if seen as a time independent figures. Although if the trend is analyzed it would give a better insight of the building phenomenon. Since it is highly recommended to see and analyze different process variables and calculated or derived variables with respect to time, various statistical methods have been devised to quantitatively assess the change in parameter over time either between two similar systems or between two separate durations. Methods like drift analysis, statistical deviation and regression analysis are some of the best analysis tool that we have incorporated in the frame work.

D. Inbuilt Diagnosing Capabilities

A very important but most functionality wise ignored aspect in the data acquisition and reporting frame work is the iterative diagnosing capabilities. There are ‘n’ numbers of process variables which act and are acquired in the frame work. The way we get close to fault is by iteratively plotting them one after the other and observing the pattern of each variable conclude to some hypothesis.

This process of diagnosing has to be more flexible at the same time more standard towards evaluating faults. This functionality is currently being implemented in the software which would assist the user to diagnose fault with moderate knowledge of system behaviour. The software application is on a whole an excellent tool to monitor, diagnose, control and provide advisory services that facilitates increase in performance efficiency, reduced energy consumption and a reduced carbon footprint of chillers and their plants. Presently, the application is in the process of being updated to cater to the Heating industry, such as Boilers and Hot water plants.

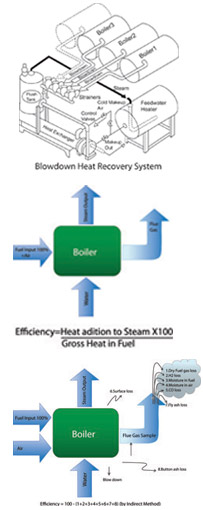

X. Boiler Analysis

Boiler is used in the heating systems represent one of the largest investment in terms of capital cost, foot print and operational cost for facility. Yet, despite these costs and impacts, many plants don’t reach their full potential in terms of capabilities and efficiency. The deep boiler analysis feature provides extensive bench marking and diagnostics tools, designed to meet a Boiler Analysiswide set of requirements .This online assessment platform helps to drive improvements to the operation of the boiler, helping to align consumption and performance to the selected benchmarks. Since heating typically can constitute 30% of the total building operation cost, managing and tracking the performance of the hot water system can often result in substantial cost savings with minimum investment. The tool set provides entirely web based and flexible frame work, which is capable of communicating with wide varieties of plants and equipment. By executing set of specially designed and integrated data mining and analysis activities, we are able to deliver critical efficiency and diagnostic information to key users. This delivers

- Performance analysis and associated calculations

- Data acquisition and arriving

- Data visualization and reporting

The frame work performs two levels of calculations: primary and secondary. Primary calculations represent a first pass analysis at incoming data from selected infrastructure components and executed against deep hardware data. Parametres from boilers, such as temperatures of water inlet, steam outlet, ambient air, skin of the boiler and stack, flow of water, steam, fuel, air, and make up water and other sets are logged and exposed to a set of algorithms. Once, the data is exposed to a secondary set of calculations. These calculations include advanced algorithms such as British standards, BS845:

1987, ASME Standard: PTC-4-1 Power Test Code for Steam Generating Units and IS 8753: Indian Standard for Boiler Efficiency Testing

XI. Smart Grid Monitoring and Analysis

Smart grid architecture helps companies and other enterprises become more energy efficient by enabling interaction throughout the entire infrastructure, including electric generation, delivery and consumption components. Energy management software is the key to saving energy and reducing costs because it automatically monitors real time energy use, weather data, and other critical systems

across the entire enterprise. This smart technology enables businesses to procure the best energy rates for their sites. Smart grid architecture enables the delivery of electricity from supplier to consumer through digital technology. Smart grid architecture is effective in any type of enterprise, but is more advantageous in retail stores, warehouses, production facilities, hospitals, universities and other large or multi-building ventures. Because all systems are automated and metered, they track when and how much electricity is used.

By combining smart grid architecture with energy management software that provides real time energy use, businesses can better manage their energy consuming equipment and their cost of electricity use. Since the price of electricity increases during high demand periods and decreases during off-peak times, enterprises that use energy management services can reduce their demand during high cost times. Our solution involves the ability to measure or monitor electricity use as a function of time of day, power quality characteristics such as voltage level, current, cycles per second, and to store, synthesize or report that information. This coupled with the ability to sense and localize disruptions or changes in power flows on the grid and communicate such information instantaneously and automatically for purposes of enabling automatic protective responses to sustain reliability provides a unique solution towards going green using an automated, digital grid, and reduce pollution with a more efficient operation. Among the benefits are reduced costs, energy savings, enhanced reliability, more efficient demand response, and the ability to use renewable energy. The methodology involves several measurement devices such as smart meters and phasor measurement units over the Grid, starting right from the generation point to the end consumer as depicted in the grid monitoring architecture drawing. The measurement points are connected over a GPRS network, GPS network connected in the case of phasor measurement units into our Global Command Center wherein we combine the smart grid architecture with energy management software that provides real time energy use, we can better manage energy consuming equipment and the cost of electricity use.

Remotely Managed Energy and Facilities Management Services For Buildings and Infrastructure: Carbon Footprint Analysis

The carbon footprint is a powerful tool to understand the impact of global warming. Most people are shocked when they see the amount of CO2 their activities create! If you personally want to contribute to stop global warming, the calculation and constant monitoring of your personal carbon footprint is essential. The total amount of greenhouse gases produced to directly and indirectly support human activities, usually expressed in equivalent tons of carbon dioxide (CO2).

The developed solution accounts for carbon emissions from commercial buildings, educational Institutions, banks and financial institutions, government service Infrastructure like airports, ports and railway infrastructure, residential buildings, data centers industrial facilities, telecom infrastructure and power distribution network due to various activities and energy consumptions in various forms.

The introduction and ratification of Kyoto Protocol by a number of countries on the issue of climate control has made countries to look at the issue of environmental sustainability in a new light. Kyoto Protocol has opened the route for initiating sustainable development with an added dimension of commerce, thereby, making environmental conservation also a successful commercial model.

It was of utmost importance to develop a mechanism for accounting of Carbon Emissions for any level of buildings. The traditional approach of accounting includes use of worksheets where data is collected manually. The data is then compiled and calculated to give you the amount of emissions as a whole. The process becomes tedious and there is high probability of error due to human interface.

Pacific Controls has developed a potential application software that addresses and provide a definite amount of value add for it users. The application incorporates a number of technological advancements that makes the task of calculation of carbon footprint more streamlined and consistent. With Pacific Controls smart metering technology buildings and infrastructure will be able to monitor how much energy individual devices use. The typical building for instance has devices such as chillers, AHU’s, FCU’s, pumps,fans and the IT load that are continuously on. Nearly 20% to 30% of the average energy consumption could be influenced by Pacific Controls software. Users can use the interactive energy management tools to create energy management profiles that are triggered by certain established consumption rates. As energy consumption exceeds a specific point, the system can automatically begin turning off low priority lighting, heating, and cooling zones. An effortless way to green your space is to take control of your energy consumption by finding out exactly how much you are using. Armed with software tools, you can measure how much electricity a device uses, or find out how much electricity your whole workspace uses. The application provides monitoring of cost of electricity usage as per laid down tariffs based on slabs or any other rate patterns such as peak rates and off-peak rates. It can be programmed to reflect two rates one for off-peak periods and one for peak periods so you know how much money you’re spending on electricity at any given time. Once you determine these facts, you can reduce usage or replace energy consuming devices with more efficient items. These real-time energy usage indices help you understand your habits and can get you to become more efficient with your energy consumption needs

- Incorporating green technology:

Pacific Controls implements its carbon footprint measurement solution into new or existing buildings which makes it easier to reduce energy consumption and the carbon footprint that is generated. Pacific Controls offers energy saving smart lighting, HVAC and appliance controls, that turn lights, air -conditioners, appliances and energy wasting loads off automatically. The system has a great impact on the energy usage too. Simply controlling curtains to block out the sun during peak periods has significant affect on your energy needs. - Real time automated data collection:

The application software collects real time energy consumption data from the workspace or asset. This involves consumption of all forms of utilities including HVAC, lighting and smart metering. The system enables you to verify your energy profile, usage patterns, cost incurred and the carbon footprint. The data is presented in a user friendly way in form of tables, graphs and charts. - Carbon footprint on the cloud:

The system provided is totally web based and is accessible from anywhere anytime using the pervasive internet. Moreover, the system has the capability to collect data remotely for analyzing consumption patterns and Pacific Controls provide advisory services on how energy usage and carbon footprints within the asset can be reduced. - Data representation:

The data on carbon footprint and energy usage patterns are represented in the form of a graphical dashboard that can be viewed using any standard browser. Pacific Controls also provides such visualization on devices such as Iphone and itouch. A typical data visualization dashboard is shown below. The system offered has the capability to verify data right from year on year level to month on month level.

Remotely Managed Energy and Facilities Management Services For Buildings and Infrastructure: Continuous Commissioning

Continuous commissioning services provide monitoring and analysis of building performance data through permanently installed metering and control equipment. The solution identifies and resolves comfort and operational problems and drives cost savings through improved efficiency and capabilities.

When it comes to the operation and optimization of building systems, managers and operators face two core challenges: non-performance and a lack of change management.

Often, it is assumed that whatever does not work, was not installed properly, or was not tested fully will be identified and corrected by the appropriate subcontractor during the warranty period. However, even if a non-performing system is corrected, the cost (waste) in terms of dollars, kilowatt-hours, will have been substantial

In most cases, relatively simple pneumatic controls have given way to direct digital controls (DDC) and a host of new technologies, such as PID, BACnet, LON, Ethernet, ARCnet, TCP/IP, WAN, LAN, WAP, WML, XML, CORBA, SOAP, and enterprise. Managing change with respect to integration and control complexities and to achieve a system interoperability has always been an area of concern for an optimal operational management planning. Many building owners assume that once one of these services is performed, nothing more needs to be done. System degradation and whether their building continues to operate at peak efficiency are not on their radar. Equipment’s operational parameter fine tuning should be done on a continuous basis to keep building operation at an optimum level. Continuous commissioning service element of Pacific Controls offering is a process that can provide tremendous benefits for buildings and infrastructure operational management.

Pacific Controls Continuous commissioning methodology Continuous commissioning is an ongoing process to resolve operating problems, improve comfort, and optimize energy use. Typically, it consists of the following steps:

- Identify and quantify potential measures and savings.

- Develop performance baselines for energy and comfort.

- Examine the building operational parameters to identify operating and comfort problems, degradation and causes of system inefficiency.

- Implement continuous commissioning measures.

- Identify changes in operating procedures and document energy savings and comfort improvements.

- Track, measure and verify energy and comfort performance. Continuous monitoring and respond to changes.

Today’s buildings are fabricated with energy efficiency as a core facet of development and sustenance, Devices such as Variable Frequency Drives (VFD), efficient chillers and power savers are designed into major infrastructure constructions. These additives are not sufficient to provide a long term plan for optimum energy use. The system of Continuous Commissioning ensures this long term commitment and also enhances the reliability and the comfort of building owing to dynamic conditions. The ROI on a CC system are less than 3 years and the reduction in the energy consumption from 10 -20% through enhanced operational strategies. Alteration of the fundamental process of operation ensures sustainable energy usage. The imbalance between Global energy supply and demand and a collective increase in a efficiency culture has drawn energy based considerations to every day decision making.

Pacific Controls continuous commissioning process driven approach is a unique and cost-effective way to reduce energy consumption in commercial buildings and infrastructure.

Remotely Managed Energy and Facilities Management Services For Buildings and Infrastructure: Fault Detection and Diagnostics

Pacific Controls advanced dynamic fault detection; diagnostics (FDD) software monitors all the connected facility equipment and detects problems and alerts. It also provides a list of the actions that can be taken to resolve the problem

The degree of automation of processes requires a number of mechanical electronic components. In order to maintain the dependability and availability despite of the increased complexity, the methods for the quality assurance of mechanical-electronic systems are necessary. An automatic diagnostic system for the process and system under investigation are used in order to extract detailed information using the usually measured signals by evaluating the signals by parameter estimation and state estimation. Some relations, especially the cause and effect relations between the underlying faults and the observable symptoms are quite tricky to represent by analytic models. The adopted rule-based approach is more suitable to acquire, represent and process the diagnostic knowledge base. The suite of diagnostic applications runs on a centralized, web-accessible server. Any changes and improvements to the data analysis and diagnostic methods can be implemented quickly and easily at a central location. The primary target utility for this suite of applications is the buildings with built-up systems. The purpose of the diagnostic applications is to find problems related to energy waste and higher uptimes. The adopted Methodology adopts an iterative cyclic process:

- Compare actual readings to expected performance

- Determine possible diagnostic errors that could cause a deviation

- From an array of tests determine the most likely cause or multiple causes of the error