OEM Partnerships

OEM’s Aftermarket Services

Original Equipment Manufacturing (OEM) Industry has been going through revolutionary changes for the past three decades. Western economies that were at the top of global market landscape have been facing challenges to sustain manufacturing business. Emerging economies such as China, India and Brazil have improved their ranking in the overall global marketplace.

In order to sustain and grow business, the role of aftermarket services for OEM industry cannot be over emphasized. Typically producing capital goods, new sale in manufacturing industry is prone to cyclical nature of the market – the industry is one of the worst hit sectors of the economy during recessionary periods. On the other hand massive installed base of OEMs offer attractive opportunities to deliver aftermarket services and derive significant additional revenues. To seize these opportunities, many equipment manufacturers are contemplating to restructure their organizations to become more services-led.

A study carried out by JWP concluded that top 4 strategies adopted by manufacturers to derive growth in increasingly competitive market are:

- Increasing the proportion of service revenue in the service/product mix

- Increasing revenue from preventive maintenance

- Benchmarking performance in the service management industry

- Using information technology to help analyze the business

Challenges Faced by OEMs

The aftermarket services business is still carried out on a reactionary basis. OEMs, and their distributors, find out about the need for maintenance services only when some breakdown happens. This leads to downtimes and customer dissatisfaction. OEMs face many challenges delivering aftermarket services effectively:

- Lack of visibility into operations of equipment - once a piece of equipment leaves an OEMs premises, OEMs have limited visibility about its use

- Warranties and Service Contracts are mostly based upon reactionary approach rather than proactive monitoring

- Cost of delivering service contracts is high due to necessary visits/truck rollouts for diagnosis

- Performance of equipment at customer premises is uncertain and unpredictable

- Lack of “equipment in use data” results in less than optimal product enhancements

- Intensifying competition and shrinking margins making equipment manufacturing and sale business less rewarding

OEMs are seeking for solutions to enhance their services by proactively monitoring equipment in operations and carry out predictive maintenance in order to ensure high uptimes, and better customer satisfaction – and ultimately deriving higher revenues through proactive actions and premium services.

M2M technologies together with necessary remote monitoring and management capabilities can help OEMs enhance their offerings. Visionary OEMs are seeking for tools to achieve the following KPIs for their customers:

- Higher uptime and equipment availability

- Reduced mean time between failures (MTBF)

- Minimum mean time to repair (MTTR)

- Minimal cost of down time for customers

- Minimized time to respond to performance degradation

- Customer satisfaction

OEMs can achieve these objectives by leveraging upon Internet of Things /M2M technologies. OEM can carry out proactive monitoring of equipment by using ICT enabled M2M technologies, capture useful equipment data, and carry out analytics to:

- Attain high visibility with respect to performance of equipment in operation

- Predict component failures /performance degradation from data analytics

- Gather useful intelligence for enhancement of future products

- Derive additional revenues by offering premium aftermarket services

Pacific Controls’ OEM Partnership

Pacific Controls offers a unique partnership propositions to help enhance their aftermarket services and achieve desired objectives. Pacific Controls currently enables monitoring of a wide variety of assets on behalf of OEMs and their distributors utilizing ICT enabled IOT technologies. This value proposition enable software defined machines that are capable of interacting with other machines to deliver ideal results.

Pacific Controls’ Galaxy Platform integrates millions of assets, using M2M technology, to capture massive amount of data about equipment operations with the objective to analyze that data, identify anomalies, diagnose problems and help proactively fix those problems -- before any down time could occur. Pacific Controls’ Galaxy can help Original Equipment Manufacturers (OEMs) to better serve their customers, introduce new lines of revenues and increase life and performance of equipment, which ultimately enhance customer satisfaction.

OEMs can make use of the rule-based artificial intelligence to detect and identify faults, perform fault analysis and provide diagnostics reports. Galaxy’s Fault Detection and Diagnostic tools can actively simulate or test for faults under a complete range of operating conditions to identify root causes of anomalies, thereby minimizing onsite maintenance visit.

Pacific Controls Value Proposition

Pacific Controls propositions entails:

- A remote monitoring and management service, branded for the OEM, that can help monitor key parameters of equipment performance and generate alarms for any performance degradation

- Useful business intelligence by capturing and analyzing useful data

- Compete business practice and skills transfer to rollout service

- Enabling a new premium aftermarket services without having to invest heavily in necessary tools and infrastructure

- Time to market

Pacific Controls’ White Label Service will help OEMs achieve the following objectives

- By undertaking 24 x 7 monitoring of equipment on proactive basis, and generating alarms for degradation. the service help ensure continued Uptime and equipment availability

- Proactive monitoring and remote fault detection and diagnosis help minimize chances of failure and hence Mean time between failures (MTBF) is negligible

- Remote diagnosis on detection of anomalies and fixing those problems remotely and/ providing an analysis of faults to technician, can help minimize Mean time to repair (MTTR)

- Delivering aftermarket services in a cost-effective manner, thereby improving profitability – trucks rolls are minimized due to remote monitoring and diagnostics.

- Remote monitoring and management ensures that down times are minimum and hence the cost of down time remains minimal

- As equipment is proactively monitored and collected data is analyzed, anomalies identified and problems are predicted before they cause disruption and hence Time to respond remains minimal

- Proactive monitoring and management ensures highest Customer satisfaction

Service Delivery Architecture

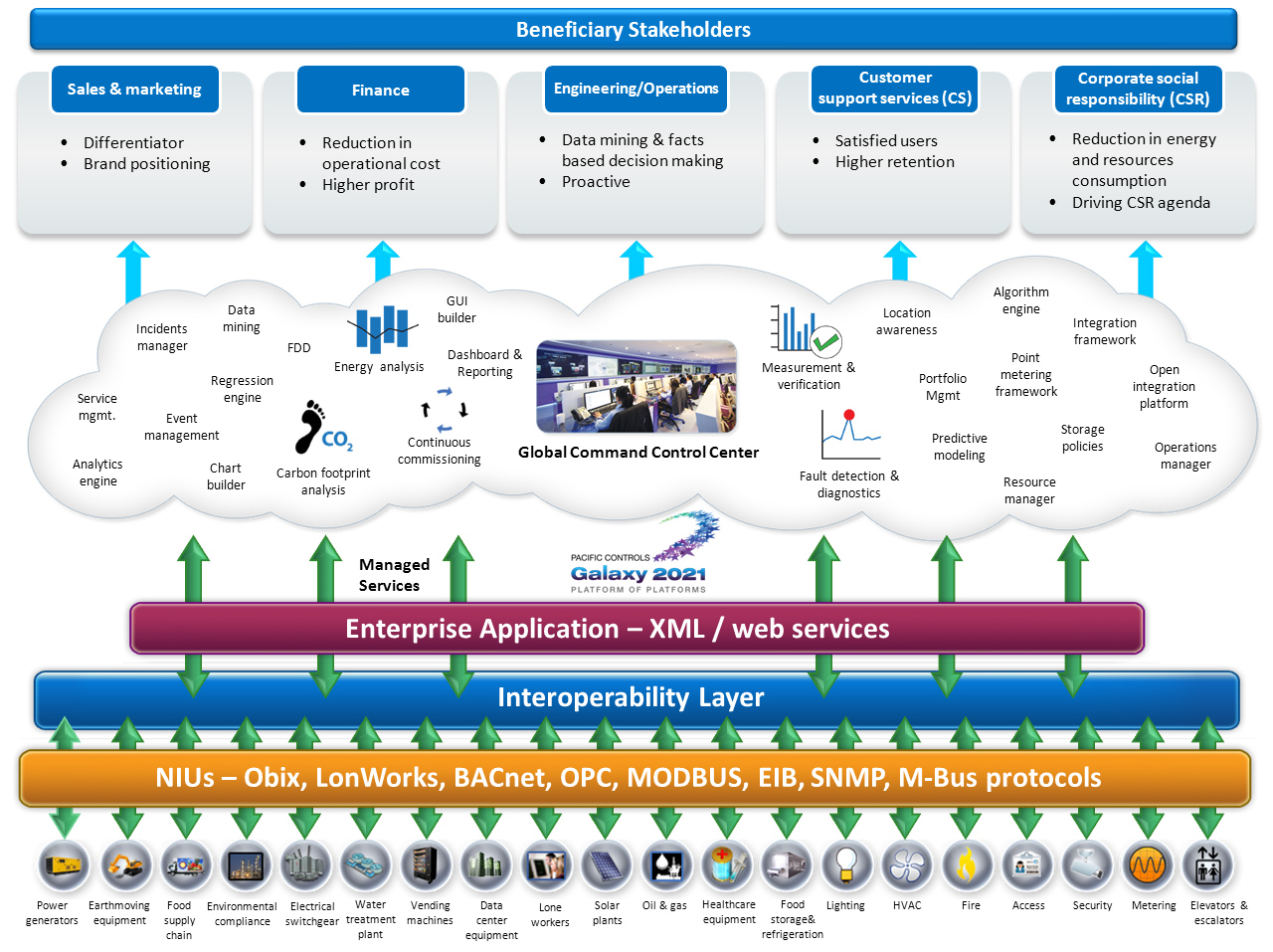

Pacific Control’s Galaxy Platform, deployed in Global Command Control Centre (GCCC), delivers unpreceedented capabilities to capture and analyze data to produce actionable business intelligence. This intelligence helps take proactive actions, undertake predictive maintenance, in order to optimize equipment performance, reduce downtimes, minimize operational costs and assist in future product enhancements. Gbots, created by Galaxy, are capable of predicting imminent component failures. Gbots intelligently extract knowledge and useful information from that data and diagnose problems. Gbots can identify early signs of malfunction through supervised and unsupervised learning, including case-based reasoning and neural network techniques. This helps OEMs provide predictive maintenance services. Global Command and Control Centers are manned with 24 x 7 resources, who are capable of identifying anomalies and take corrective actions. Pacific Controls is able to utilize numerous protocols to integrate any machine with IOT platform to capture operational data and to monitor equipment performance.

For more information on Pacific Controls’ proposition, please contact