Press Releases

Using Gbots to detect defects

Successfully detecting excess energy conditions in buildings and delivering buildings that become and stay more energy efficient.

Abstract

We have known for many years that buildings don't run very energy efficiently and that we can save around 10 to 30% of energy just by getting the existing plant and systems to work as well as they should. However translating this general understanding into specific problem and fault diagnosis, so the problems get isolated and fixed, has largely proven to be beyond our normal capability.

What is required is a set of simple to use diagnostic techniques to automatically detect the causes of the inefficient operation so they can be fixed and to kept track of if and when they recur.

This article describes using a number of techniques; Elemental Analysis, Rules Engines and particularly Gbots, a revolutionary Remote Service Delivery Technology that Pacific Controls deploy from their Cloud Based Galaxy Service Delivery Platform, to successfully detect excess energy conditions in buildings and deliver buildings that become and stay more energy efficient.

Introduction

It has been well known for many years that buildings generally don’t operate very energy efficiently. Various studies, including from DoE and others, have consistently reported that inefficiencies in the operation of Building Services result in excess energy consumption of 10 to 30% typically with an average in the 15 to 20% range. That means that just by getting what’s already in the building to work as intended we can make that significant level of energy savings.

These excess energy conditions arise from a variety of causes – poor design, installation and commissioning of systems often mean that the buildings started off badly. Poor maintenance and operational practices generally mean that these problems are not diagnosed and fixed and that other problems arise and add to the inefficiency.

Most major buildings are today fitted with so called advanced controls and Building Management Systems, but diagnosing the specific problems in a way that allows them to be identified and resolved has so far proved to beyond the capability of most of our industry.

Isolated success

There have been instances where small groups of experienced individuals have come together and made a big improvement in a portfolio of buildings. We have seen Supermarkets, Banks and School Districts getting close attention from Subject Matter Experts who can interpret the BMS information and can diagnose these excess energy states. The short term results from these initiatives show dramatic savings. Unfortunately these individuals are rare, and their success usually gets them promoted to other functions, and the buildings then revert to the business as normal scenario in a year or two.

Using Subject Matter Experts is not a scalable, sustainable solution to getting our Buildings more efficient. What are required are automated techniques that can be applied to the whole portfolio of buildings to diagnose the excess energy conditions that exist so they can be fixed. We are helped in this quest by the fundamental changes that are happening in computing. Cloud Computing, Data Centers, Big Data all give us access to phenomenally more computing power to solve these problems that we have had before.

We still need to come up with simple to use, reliable ways of detecting the excess energy conditions and this paper describes a variety of techniques that have been developed and deployed and discusses their outcomes.

Energy Information Systems EIS

The first fundamental of any management or control system is measurement. To effectively manage energy we must first measure it. That means meters will need to be installed if they don’t already exist.

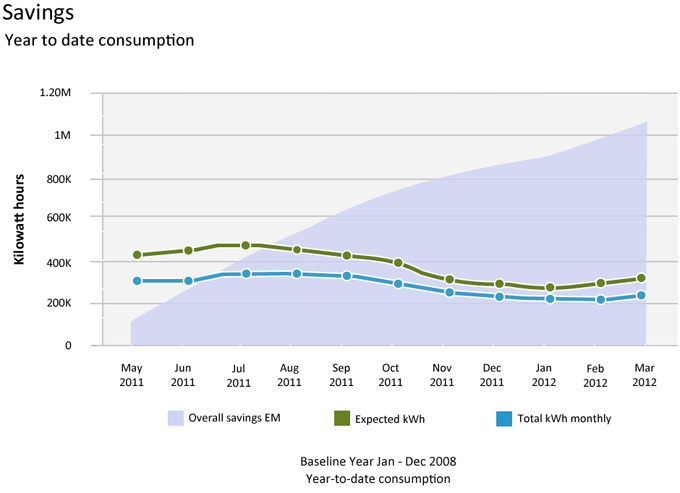

Energy Information Systems that use energy data from meters have been around for some years. You can use monthly billing data but for meaningful analysis we need higher frequency data say every 15 minutes or half hour. EIS keep track of energy consumption and using techniques like Regression Analysis and CuSum, allow us to normalize energy consumption against ambient conditions, and with those tools we can track when the buildings perform better or worse. Most importantly an EIS gives us an auditable way of calculating and tracking energy savings.

What EIS don’t do is work out what’s wrong and needs fixing. They have almost no diagnostic capability to help pinpoint the causes of excess energy consumption. Comparisons between buildings based on energy consumption per square foot are notoriously inconsistent and poor indicators of a building’s energy efficiency.

One thing the EIS does is it allow us to diagnose is when the plant is running. Running the plant longer than needed or some plant 24 hours a day is a big contributor to excess energy consumption. Of course the daily overlays graphs that show plant running when it should not are very useful but don’t tell you what plant is running, you have to figure that out by looking deeper into the systems in the building.

So an EIS is an important thing to have in order to measure and track energy savings but it won’t by itself save any energy.

Fault Detection and Diagnosis Models

A number of developers have tried to use model based systems that model how either the whole building or a particular piece of plant, like an air handler should be working and then use a rules based approach to find the differences between the actual performance and the expected to diagnose problems.

This approach has a number of inherent difficulties. It takes a considerable amount of time and work to set up or train the model about any particular piece of plant or even longer for a whole building. The rules flow that needs to be used to diagnose the problems gets very complex and difficult for the human brain to follow. So this has not proven to be a scalable or practical solution.

Elemental Analysis

A much better solution to detecting the excess energy states comes from what we are calling Elemental Analysis.

By consulting the people who actually run and operate buildings, we have found a list of the common things that go wrong in buildings and cause excess energy consumption.

These are things like;

- Plant being in manual control and so running continuously

- Temperature set points too high or too low

- Economizers on AHU’s not working properly

- Simultaneous heating and cooling

- Temperature sensor errors and so on

We have compiled a list of about 50 things that are the majority of conditions that cause excess energy consumption. These are conditions that generally don’t stop the building working satisfactorily and so don’t show up on alarm or fault reports. Instead the plant and its controls can compensate for the problems but at the expense of excess energy consumption. The conditions we want to detect on this list have been reduced down to plant components or elements rather than whole plant analysis – like the economizer dampers or the heating and cooling valves. We can detect these elemental conditions, which are the same between plants and buildings and so can be universally applied with little or no training or tuning for individual plant types. We are calling this Elemental Analysis and it has shown to be a powerful, scalable, reusable set of analytic techniques to characterize excess energy consumption.

We will now look at the algorithms to detect these elemental excess energy conditions.

State Based Rules and Diagnostics

In order to detect the excess energy conditions the plant has to be in a particular state for the conditions to be measured and recognized. For our economizers we need the plant to be running and the economizers to be in full recirculation or full fresh air. The outside, return and mixed air temperature sensors can then tell us if the dampers are working properly. For simultaneous heating and cooling we need the heating and cooling valves to be closed and to see if there is any heat gain or loss across the coils that would show valves letting by, or incorrect actuator stoking.

So to detect excess energy conditions we need to recognize when the plant element gets into its detection state and then to run some reasonably simple rules to work out if all is well or the excess energy state exists and needs attention.

To do that we can collect the relevant data on site and transport it back to our Galaxy based cloud platform. It can then parse the data set through its rules engine until it comes across the plant in a detection state – in our example the economizer fully open or closed - and then process the temperature sensor data for the same period to see if the dampers are working as they should. We have found that these techniques work well to discover the detection states and to make the diagnostic of the plant and so as to discover excess energy states.

The limitations are that the data has to be gathered at quite high frequency so there is a large amount of data to be captured and brought back to the Galaxy Platform for analysis. We are looking for the relevant few K’s of data in mega and giga bytes so we definitely need the big data approach.

Gbots for Elemental Analysis

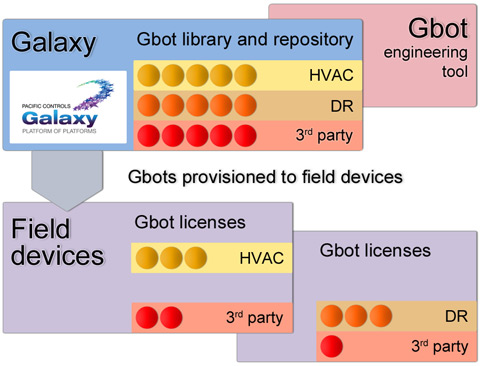

Pacific Controls have pioneered the use of Gbots in the Smart Services field. These are Remote Service Delivery components that are transmitted from Galaxy to the Gateway devices in each building to perform specific tasks.

We have developed Gbots specifically for the detection of excess energy states. Rather than passively wait for the plant to happen to get itself into a detection state we instead deploy a Gbot that forces the plant into the detection state, rather in the same way as we would manually set the plant conditions during initial plant commissioning. The economizer Gbot forces the dampers fully open and closed and measures the temperatures that result to see if the dampers are working properly. The valves Gbot forces the valves to close, waits a settling period to get any energy out of the coils and looks for any temperature change that would indicate that the valves are letting by.

Obviously these Gbots have to be deployed when their actions won’t affect the comfort of the occupants.

The merits of the Gbots for this elemental analysis are considerable. We don’t need to port loads of data back to the Enterprise Platform for analysis. If, as is normal, the data is being sent over cell phones with charges per MB of data then there is considerable cost savings. We can run the plant diagnostics when we choose prior to a scheduled maintenance so all the plant in one location can be fixed in one visit.

Optimal Control Algorithms

One further technique of optimal control also gets deployed alongside the rules and Gbots to detect the excess energy conditions. The HVAC systems and plant are designed and sized for worst case conditions of weather and occupancy but on average the actual conditions will be less severe. The optimal control algorithms vary the working point of the plant to reflect the actual conditions rather than the design conditions.

Examples of this are to reset the chiller flow temperature and flow rate based on actual demand, to change the static pressure in the duct feeding the VAV boxes based on actual conditions. Some modern control installations have this optimal control, sometimes called demand based control, already built in. Most do not and this is another valuable source of energy savings to add to the project without changing out any of the plant.

Results and Conclusions

Elemental Analysis, Rules Flows and Gbots have been deployed to detect excess energy states in buildings. They have successfully been used to detect long standing conditions in the plant that had previously evaded detection by conventional analysis resulting in considerable energy savings from buildings that were considered well run and already efficient. The approach has proved to be scalable, reusable and automatic.

Optimal control algorithms successfully reset plant conditions to fulfill requirements at maximum efficiency. So this approach allows us to look forward to being able to automate the energy efficiency process in our buildings and realize the potential energy saving that have been recognized but not achieved for so long.

This article was published by www.automatedbuildings.com in July 2012

Terry Casey

Chief Strategy Officer,

Pacific Controls